What exactly is a composite structure and what distinguishes it from conventional steel and concrete solutions?

If you pour concrete into a hollow beam, will it automatically become a composite beam?

The answer is no. There are several requirements that must be met to create a working composite product, and the key is that the different materials must work together. It requires some form of connection, between the materials.

Uncertainty in the market

Today, there is some uncertainty in the market about what is a composite product, and different terms are easily confused. For example, it is not uncommon for us at SWT to receive a request for delivery of composite beams, but then later in the specification see mentioned concrete-filled HSQ beams. But filling a box beam, like an HSQ beam, with concrete does not automatically make it a composite beam. Assuming this can be dangerous as it can lead to undersized designs.

Not all hat beams are the same

An HSQ beam is normally smooth on the inside, i.e. it is a hollow box without either reinforcement or anything else that the concrete can grip. There is thus no mechanism for transferring the so-called shear forces between steel and concrete. Having shear connectors is a requirement according to Eurocode 4, the European standard that governs the construction of composite structures.

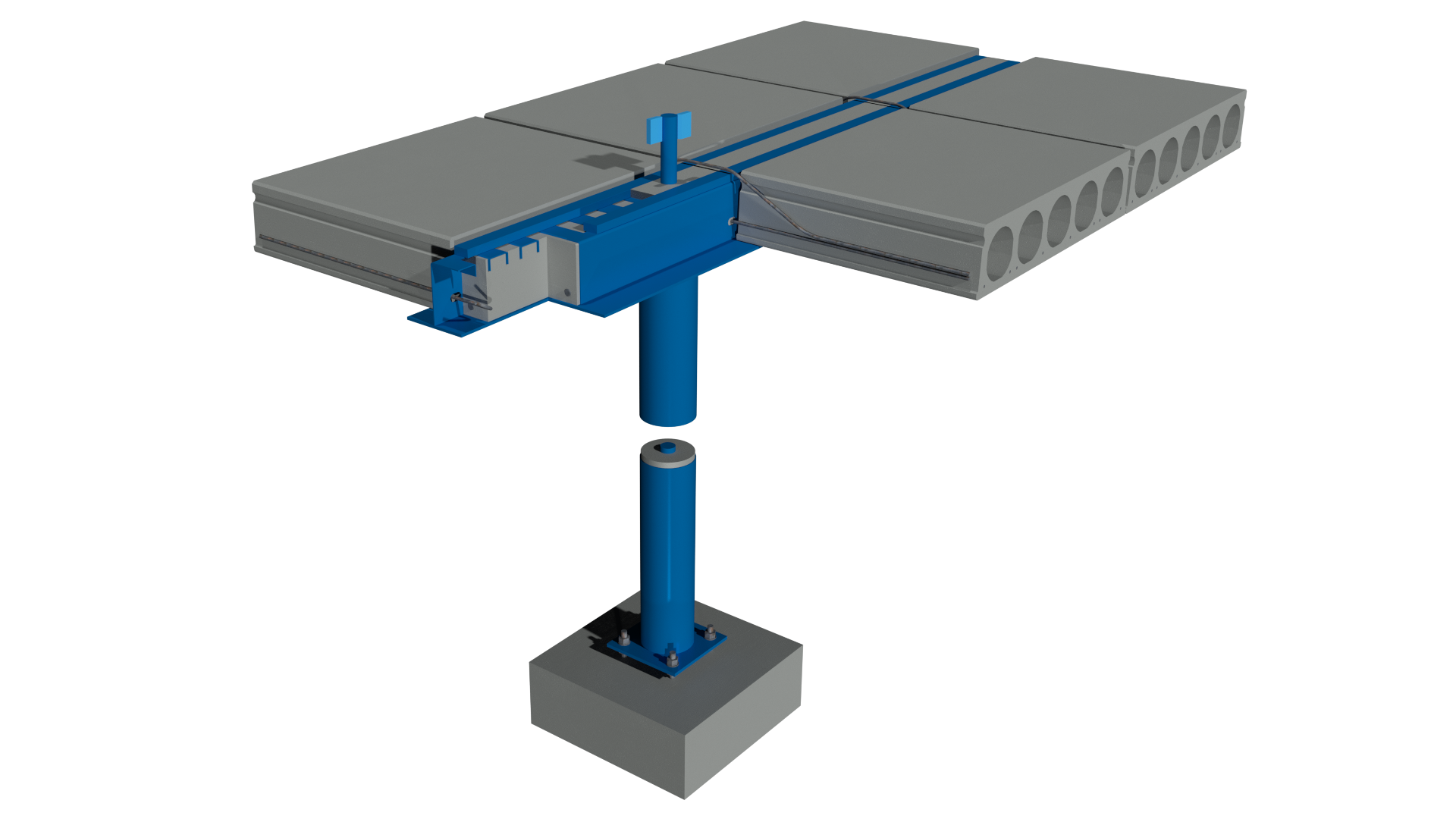

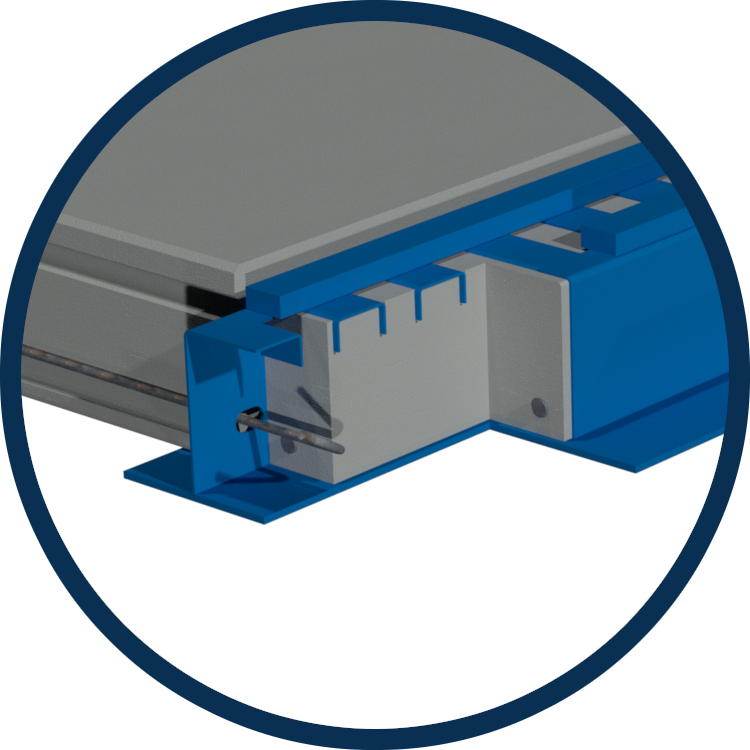

The SWT beam meets the requirements through the folded flanges at the top and the reinforcement at the bottom. The function is verified with tests, where the adhesion was measured as the concrete was attempted to be pushed out of the beam. It was proven that the adhesion was many times higher than the requirements.

If you build the beam into the floors, will it then be a composite beam?

Not necessarily. If the beam lacks fixed and required shear connectors, it is not a composite beam, as the concrete can slide against the steel and also completely fall off as nothing holds the materials together.

The history of the composite beam

The early composite beams consisted of conventional I- or H-profiles, where studs were welded on top and reinforced together with the joists on top. This resulted in increased capacity because an extra lump of concrete was obtained at the top that could handle compressive forces.

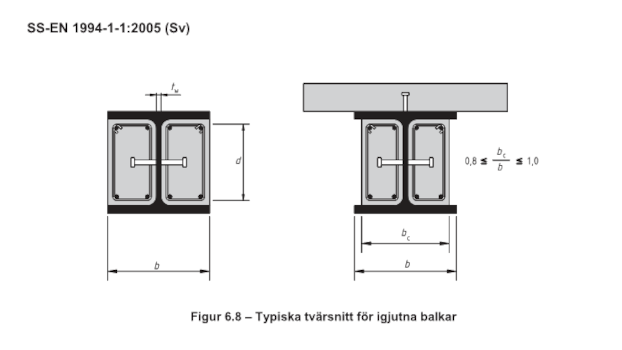

A further development of this was to cast in the rest of the beam as well. This further increased the capacity and provided some fire protection. However, just as in the modern hat beams, it is required that steel and concrete are connected. Studs or loops of reinforcement must be welded on the beam webs to keep the concrete in place. This is exemplified in the image below, which is from Eurocode 4.

A problem with the single-web beams is that they have low torsional rigidity in the steel cross-section, compared to beams with double webs (box profiles). This means that they must be propped during the assembly phase, which can be costly on the construction site. A hat beam, like the SWT beam, is torsionally stiff enough to handle the assembly loads without torsional propping along the beam span.

Composite elements in fire

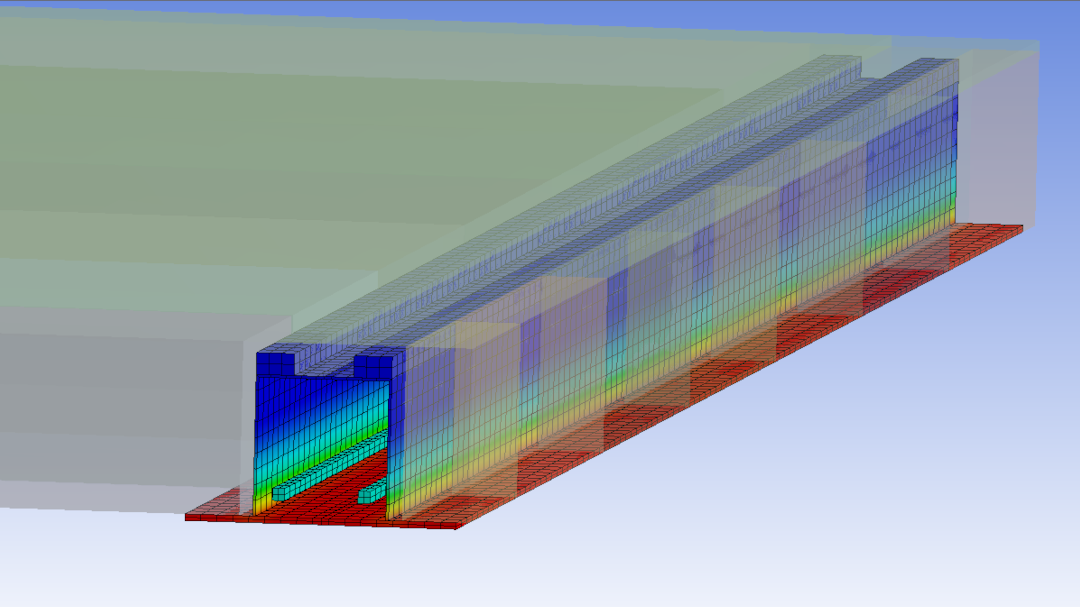

One of the great advantages of composite elements, is that they can be designed to meet fire requirements without external protection. The concrete has good heat-insulating properties compared to steel, which means that a large part of the cross-section, except that which is directly exposed to the fire, has a lower temperature and maintains good load-bearing capacity.

For the parts that are exposed, e.g. the beam flange and the column casing, there is residual capacity in the concrete and the internal steel structures (reinforcing bars in the beam and the core in the column) that can take over loads from the heated parts. Since the total load in fire, according to Eurocode, is lower than in a cold situation, it is usually possible to achieve a high degree of optimization of the design in both cold and fire situations, through smart choices of components.

The SWT beam and the SWT column are both tested and extensively analyzed in fire situations.